The Highest Technology With Automatic Waste Plastic Pyrolysis Plant Design

- By Tanya Granados

- •

- 12 Jun, 2017

- •

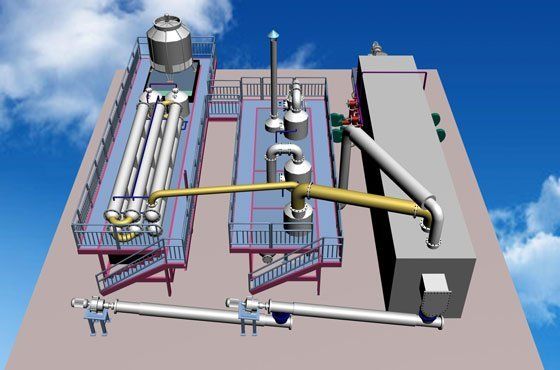

Automatic Waste Plastic Pyrolysis Plant Design

Automatic Waste Plastic Pyrolysis Plant Design Technology

The present day automatic waste plastic pyrolysis plant design is made with technology, which can be well researched and experimented. Automated pyrolysis plant reflects low-cost investment with higher-volume as well as-quality product output. The automated design combines automatic and batch pyrolysis processes that cause efficient and time-saving plastic pyrolysis. The raw materials are continuously fed from one side along with the end products fuel oil, steel wire, and carbon black are continuously released in the opposite end. The automated waste plastic pyrolysis plant design offers an excellent green technology that aims at achieving eco-friendly pyrolysis process with a commitment of the excellent plastic waste management system.

High-Quality Byproduct Output with Automated Plastic Pyrolysis Machine

Pyrolysis plant manufacturers have worked tirelessly to discover a technology that will solve the current plastic waste problem. Pollution has become a constant challenge inside environment and around the world, and this is why why engineers operate tough to design a waste recycling plant that is certainly meaningful on the environment and investors. The automated waste plastic pyrolysis plant is for more opportunities within the waste recycling industry. These treadmills are made to produce high-quality product output that can be used for that professional purpose. By way of example, the oil byproduct produced with the automated pyrolysis plant is not hard to convert into vehicle fuel. This oil will require a cheaper and practical distillation tactic to convert to useful oil as in comparison to the oil that is certainly created by old design pyrolysis machines.

The byproducts of automatic waste plastic pyrolysis plant design result to large volumes. They have the capacity to producing byproducts ranging inside the following quantity: 45%-50% oil, 30%-35% Carbon black and 10%-15% steel wire. In addition to the above high volume products, the automated process produces 8% gas, that is utilized to the pyrolysis process the exact same machine.

Superiority of Automated Waste Plastic Pyrolysis Plant

The technical superiority of automatic pyrolysis plant design is the roll-out of new heating structures. These structures combine direct heating and hot-wind heating that coverts the raw material into byproduct from the first chamber. The modern heating process enhances efficiency, raise the machine lifetime, minimizing cost hence translating to high-quality investment. Customers who've used different pyrolysis operation machines will testify how the automatic machine includes a direct roi not only is it an answer that can quickly solve the present environmental problems.

What is the All Rounded Safety of Automated Pyrolysis Waste Plant?

Senior environmentalists who are seeking pyrolysis machines will discover a plant with a complete mechanism of treating industrial waste through a single process. You will find little wastes with automatic pyrolysis plants suggesting that this equipment is the long time awaited resource. Automated machines don't have a hazard of reducing sulfide waste to the environment due to the 100% safety design links with these machines. Both environment and workers are guaranteed of safety. This equipment is developed to reduce environmental hazard and improve health. Therefore, they must deliver their purpose.

The present day automatic waste plastic pyrolysis plant design is made with technology, which can be well researched and experimented. Automated pyrolysis plant reflects low-cost investment with higher-volume as well as-quality product output. The automated design combines automatic and batch pyrolysis processes that cause efficient and time-saving plastic pyrolysis. The raw materials are continuously fed from one side along with the end products fuel oil, steel wire, and carbon black are continuously released in the opposite end. The automated waste plastic pyrolysis plant design offers an excellent green technology that aims at achieving eco-friendly pyrolysis process with a commitment of the excellent plastic waste management system.

High-Quality Byproduct Output with Automated Plastic Pyrolysis Machine

Pyrolysis plant manufacturers have worked tirelessly to discover a technology that will solve the current plastic waste problem. Pollution has become a constant challenge inside environment and around the world, and this is why why engineers operate tough to design a waste recycling plant that is certainly meaningful on the environment and investors. The automated waste plastic pyrolysis plant is for more opportunities within the waste recycling industry. These treadmills are made to produce high-quality product output that can be used for that professional purpose. By way of example, the oil byproduct produced with the automated pyrolysis plant is not hard to convert into vehicle fuel. This oil will require a cheaper and practical distillation tactic to convert to useful oil as in comparison to the oil that is certainly created by old design pyrolysis machines.

The byproducts of automatic waste plastic pyrolysis plant design result to large volumes. They have the capacity to producing byproducts ranging inside the following quantity: 45%-50% oil, 30%-35% Carbon black and 10%-15% steel wire. In addition to the above high volume products, the automated process produces 8% gas, that is utilized to the pyrolysis process the exact same machine.

Superiority of Automated Waste Plastic Pyrolysis Plant

The technical superiority of automatic pyrolysis plant design is the roll-out of new heating structures. These structures combine direct heating and hot-wind heating that coverts the raw material into byproduct from the first chamber. The modern heating process enhances efficiency, raise the machine lifetime, minimizing cost hence translating to high-quality investment. Customers who've used different pyrolysis operation machines will testify how the automatic machine includes a direct roi not only is it an answer that can quickly solve the present environmental problems.

What is the All Rounded Safety of Automated Pyrolysis Waste Plant?

Senior environmentalists who are seeking pyrolysis machines will discover a plant with a complete mechanism of treating industrial waste through a single process. You will find little wastes with automatic pyrolysis plants suggesting that this equipment is the long time awaited resource. Automated machines don't have a hazard of reducing sulfide waste to the environment due to the 100% safety design links with these machines. Both environment and workers are guaranteed of safety. This equipment is developed to reduce environmental hazard and improve health. Therefore, they must deliver their purpose.